Measurement

of wire sizes - standard wire gauge - outside micrometer

Necessity of measurement of wire

size:

Ø The measurements determine the amount

of current that can safely pass through the wire without generating damages.

Ø Wire

gauge refers to the physical size and current carrying capacity of the wire.

Ø To

find out the thickness or diameter of a conductor we use SWG and outside Micro

meter.

Measurement of wire size by

Standard Wire Gauge:

The standard wire gauge measure the wire size in SWG

numbers from 0 to 36. According to the standards each number has an assigned

diameter in inch or mm. It should be noted that the higher the number of wire

gauge the smaller is the diameter of the wire. The slot in which the wire just

slides in is the correct slot and the SWG number could be read in the gauge

directly.

Measurement of wire size by

American Wire Gauge (AWG):

The American wire gauge is different from the

British standard wire gauge. In an American wire gauge (AWG) the diameter is

represented in mils rather than inch or mm. One mil is one thousandth part of an

inch.

Measurement

of wire size by Outside micrometers:

Outside Micrometers are

used for measuring the thickness or outside diameter of small

parts. They are industry standard measuring tools because of their high

accuracy/resolution and ease of use. It is used to measure a job, generally

within an accuracy of 0.01 mm.

The

parts of a micrometer

Frame:

The

frame is made of drop-forged steel or malleable cast iron.

Barrel/sleeve:

The

barrel or sleeve is fixed to the frame. The datum line and graduations are

marked on this.

Thimble:

The thimble is attached to the spindle and on the bevelled surface of the

thimble, the graduation is marked.

Spindle:

One end of the spindle is the measuring face. The other end is threaded and

passes through a nut. The threaded mechanism allows for the forward and

backward movement of the spindle.

Anvil:

The anvil is one of the measuring faces which is fitted on the micrometer

frame. It is made of alloy steel and finished to a perfectly flat surface.

Spindle

lock-nut: The spindle lock-nut is used to lock the spindle at

a desired position.

Ratchet

stop: The ratchet stop ensures a uniform pressure between

the measuring surfaces.

Specification:

Outside micrometers are available in ranges of 0 to 25 mm, 25 to 50 mm, and so

on. For electrician, to read the size of the wire 0 to 25 mm is suitable.

Least Count: Least count can be

defined as the smallest division on main scale to the total no of division on

circular scale.

Skinning of cables:

Skinning is the process of removing insulation from

the wire and cable. By using Electrician knife (at 200 angle to the

axis of the core or conductor) and wire stripper.

Wire Stripper:

A wire

stripper is a hand tool used by electricians, for removing the

protective coating of an electric wire in

order to replace or repair or joint the wire.

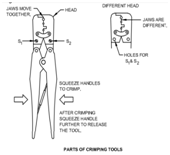

Crimping

tool:

Crimping tools are used

to make joints between two wires or a wire and a connector, such as lugs.

Cable Lugs:

Cable lugs are

used for connecting cables to

electrical appliances, other cables,

panel, surfaces, or mechanisms.

The current carrying capacity of a particular area

of cross section cable depends upon the following factors.

• Type of conductors

(metal)

• Type of insulation

• Cable run in conduit

or in open surface

• Single or three phase

circuit

• Type of protection -

coarse or close excess current protection

• Ambient temperature

• Number of cables in

bunches

• Length of circuit

(permissible voltage drop) - this will be discussed at a later stage.

Depending upon the above factors the current rating

of cables may vary to a great extent. Information in this lesson will enable

the wireman to select the correct cable under normal working conditions

Classification

of voltage grading:

Voltage is classified as

1. Low voltage (L.V):

Normally not exceeding 250V (i.e.) from 0 to 250 volts.

2. Medium voltage

(M.V): Exceeding 250V but not exceeding 650V from 250 to 650 volts

3. High voltage (H.V):

Exceeding 650V but not exceeding 33000V.(650-33000 volts)

4. Extra high voltages:

All voltages above 33000V comes under this category.

0 Comments