Methods of magnetizing - Shape of Magnet - Care & maintenance of Magnet

Methods of magnetizing:

There are three principal methods of magnetizing a material.

- Touch method

- By means of electric current

- Induction method.

Touch method:

This method can be further divided into:

- Single touch method

- Double touch method, and

- Divided touch method

Single

touch method: In the single touch method, the steel

bar to be magnetized is rubbed with either of the poles of a magnet, keeping

the other pole away from it. Rubbing is done only in one direction. The process

should be repeated many times for inducing magnetization of the bar.

Double touch method: In this method the steel bar to be magnetized is placed over the two opposite pole ends of a magnet, and the rubbing magnets are placed together over the centre of the bar with a small wooden piece in between.

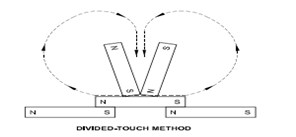

Divided touch method: Here the two different poles of the rubbing magnets are placed as in the previous case. They are then moved along the surface of the steel bar to the opposite ends. The rubbing magnets are then lifted off the surface of the steel bar and placed back in the centre of the bar. The whole process is repeated again and again.

By electric current:

The bar to be magnetized is wound with

an insulated copper wire, and then a strong electric current (DC) from a

battery is passed through the wire for some time. The steel bar then becomes

highly magnetized. The magnet made by such an arrangement is called an

electromagnet and is generally used in laboratories.

Induction method:

In this method a pole charger is used which has a

coil of many turns and an iron core inside it.The direct current supply is fed

to the coil through a push-button switch. The steel piece to be magnetized is

placed on the iron core kept inside the coil. The iron core now becomes a

powerful magnet, and thus the steel piece is magnetised by induction.

This is a commercial process for making

permanent magnets for speakers, telephones, microphones, earphones, electrical

instruments, magnets, compasses etc.

Shapes of magnets:

Magnets are available in various shapes, which are given below-

- Bar magnet

- Horseshoe magnet

- Ring magnet

- Cylindrical type magnet

- Specially shaped magnets

Care and maintenance of permanent magnets:

- Permanent magnets should not be thrown or dropped.

- They should not be hammered.

- They should not be heated.

- Bar

magnets should be placed side by side with their ends facing opposite polarity,

with keepers at their ends.

0 Comments